Selecting Appropriate PV Array String Sizes

By: Kent Osterberg

Reference: HP online magazine

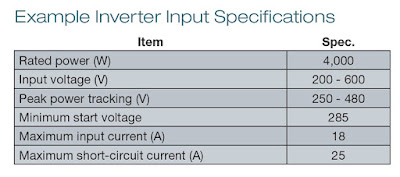

To appropriately size a PV array to an inverter, it is necessary to make sure that the:

• PV array never generates more voltage than the inverter’s maximum allowed input voltage

• Voltage remains within the inverter’s maximum power-point tracking range

• Current is within the inverter’s maximum current and short-circuit current specifications

• Power rating is appropriate for the inverter.

Equipment Specifications

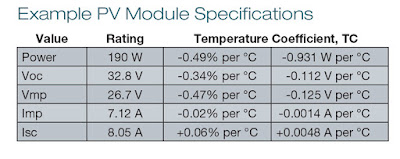

Module specs can be found on the manufacturer’s data sheet or on the back of the module. The values shown in the table are for a 54-cell module. The manufacturer includes a temperature coefficient for the peak power voltage. If the temperature coefficient for peak power voltage is not published, then the temperature coefficient for peak power, in percent, may be used as an approximation. Similarly, inverter specs may be found on the inverter data sheet or its label.

Temperature Data

Because a PV module’s output depends on its temperature, calculations also must account for the lowest and highest possible site temperatures. One source for record temperatures is weather.com; another is SolarABCs.org, which has an interactive ASHRAE data map. A table of ASHRAE temperature data can also be found in “Expedited Permit Process for PV Systems” at SolarABCs.

For the first computation, which low temperature should you use—the ASHRAE tables’ “extreme minimum” or the record minimum from the local weather station? The “extreme minimum” is a little misleading—half of all years will have at least one day that is colder than this temperature. The “extreme minimum” is actually the average annual minimum temperature. Since inverters should never see a voltage that exceeds the maximum input voltage, I choose to use the more conservative method—the record low temperature. If you use the “extreme minimum” temperature, you may get one extra module in the string, but on some cold winter day, that extra module may result in damage to the inverter or void its warranty.

Calculate the Maximum Number of Modules in Series

The equation to solve for the maximum number of modules in series is:

Using example data from the table:

Since we have to work with whole modules, 15 modules is the maximum that can be wired in series.

Calculate the Minimum Number of Modules in Series

There are two factors to consider—PV module output degradation over time, and the effects of high temperature. Most studies of PV module degradation focus on power, concluding a median value for module power degradation of about 0.5% per year. Recently, the National Renewable Energy Laboratory (NREL) studied 12 mono- and poly-crystalline PV modules to see how the current and voltage parameters change over time. Relative to determining inverter string size, the significant finding was that 10 out of 12 modules showed less than 0.2% per year degradation in Vmp, with Voc remaining essentially unchanged. Since we’re estimating a PV module lifespan of more than 25 years, we need to consider that Vmp may drop by 5% over the system’s life: 0.2% per year × 25 years = 5%.

For the temperature factor, the ASHRAE “annual design dry-bulb high temp” value (either 2% or 0.4%), or the record high temperature may be used. The 2% temperature factor means only exceeding 2% of the time in the months of June, July, and August. The 0.4% temperature factor is only exceeded 0.4% of the hours during the hottest month—but there may be other months that it is exceeded. The temperature selected will determine how many hours every year the inverter may deviate from the maximum power point voltage.

Using the 2% temperature value will result in about 42 hours over the summer when the inverter may operate off its peak power point. With the 0.4% temperature, the inverter may operate off the peak power point for three hours during the hottest month of the year, and probably a similar number of hours for the other two summer months. If the record high temperature is used, the inverter should always be able to track the maximum power point. Since a small energy loss is far less critical than an inverter failure, there is no need to be conservative about which one is used. The sample documents provided in “Expedited Permit Process for PV Systems” use the 2% value. In my Oregon location, to be eligible for incentive money, I’m required to use the more conservative 0.4% temperature, which is used in the following calculation:

The minimum number of modules in series is 13 modules:

Since these modules are sitting in the sun and heating up during the day, the PV cell temperature will be hotter than the ambient air temperature and thus a temperature “adder” is used to estimate the PV module’s cell temperature. Different temperature adders are used depending on the array mounting method (see table). This example assumes a roof-mounted array, for a temperature adder of 35°C.

Find the Maximum Number of Module Strings

The maximum number of module strings in parallel is the smaller of:

No temperature corrections are used because they are extremely small for current and because the inverter will simply clip power (rather than sustain damage) if current is higher than it is rated for.

Sizing the Array

Since PV modules generally operate at lower output compared to their standard test conditions (STC) rating, inverter manufacturers commonly specify a maximum array size up to 125% of the inverter output rating. Given a 4,000 W inverter, up to 5,000 W of PV modules (4,000 × 1.25) could be installed. In this example, the maximum number of modules would be 5,000 W ÷ 190 W per module = 26.3, i.e., 26 modules.

The possible combinations that may be considered for this inverter are: one string of 13, 14, or 15 PV modules or two strings of 13 PV modules. If we go with two strings of 13, we have a final array size of 4,940 W. Note, since one string would be at most 2,850 watts, it would be appropriate to select a smaller inverter for a single string of modules. But keep in mind the calculations will have to be repeated for the smaller inverter.

***

For residential/commercial roof top projects please email us: inquiry@eastgreenfields.com or visit our website: www.eastgreenfields.com

No comments:

Post a Comment