Reference: BY DAMAN COLE APRIL 27, 2016 IN MARKETS, TECHNOLOGY

Yingli Blog

As one of the fastest growing industries, there are many opinions and marketing taglines used which ultimately result in many misunderstandings.

Below are contradictions that you may have come across before:

1. All solar panels look similar, are they the same?

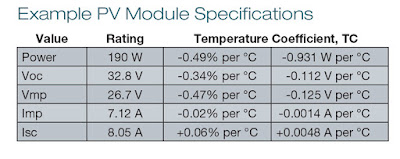

With over 500 brands that have been sold within the Australian market (between 2011-2015), it’s difficult for even an experienced professional to tell the difference. Accepting the idea that the label or datasheet has typical information as below – doesn’t mean they’re all the same:

- 10 year product warranty

- 25 year performance warranty

- Power class rating (eg. 250wp/260wp)

The manufacturers around the world have gained the majority of their market share through their ability to manufacture high standard products, which demonstrates a high level of research & development including exposure to different types of environment and life cycle tests. These are seldom regarded as important in the eyes of many retailers and consumers.

The best way to determine global exposure is asking for project references in other countries. Chances are if evidence can be provided that the products are used in larger projects in a number of other markets – there has been enough due diligence to suggest it will work for you in your market.

2. Kilowatts & Kilowatts – (kW, kWp, kWh)

Traditionally there is much confusion on this topic for non-technical buyers. Also, it’s commonly referred in the retail spaces that you are buying a system size.

For example, solar systems in Australia are sold as “5kW systems”, but really should be sold as 5kWp.

- The ‘p’ indicates “peak”, as in the amount of power being generated at peak production (being 1,000 w/m2 irradiance of direct sunlight).

- Kilowatts are the measurement of energy units. When referred as kWh (kilowatt hours), it means the energy used at a constant rate over a period of time.

- Referencing of kW or kWp does not indicate the yield or likely performance over a day, week, month or year – providing an unrealistic outcome of the solar system’s potential. It’s like saying a car that drives at 200km/h is a “200km car” – where in truth it’s only highlighting the ‘peak performance capacity’.

Once again, if larger global projects have specified and used a nominated brand of product, it is because their independent and technical due diligence suggests there is high level of confidence in a manufacturer’s ability to consistently create a product that generates a reliable quantum of electricity generation year on year.

3. What does “Tier 1” mean?

The solar industry has struggled for years with a methodology to rank and assess the relative strengths of PV manufacturers. In the absence of a true quantifiable testing regime, many have resorted to the views of financial analysts. In many instances, the industry use this term as a mean of quantifying quality, without placed onus on any specifics.

The tier system is a ranking structure used by varying financial analysts and firms. The most commonly accepted definition is based on “bankability”, which ultimately is a determination based on whether projects using the solar products are likely to be offered non-recourse debt financing by banks.

Other definitions and interpretations of ‘tier-ranking’ have included theories around vertical integration of product, presence of a local office and support, all of which indirectly suggests a level of product quality or after-sales support.

Tier-ranking can be highly subjective without substance of what it actually defines.

YGE Global - Photos - R&D, Lab, Testing - 01

The reference of a product’s country of origin is an age old method of oversimplifying quality, by providing an emotive feel good to buyers – which supersedes the requirement for further due diligence.

Solar PV has been one of the most rapidly expanding industries within a manufacturing sector for years, however with this rise, it has seen significant players trip, if not fall through this massive growth phase. Many manufacturers prefer to diversify their base and expand by opening many plants around the world. It simply isn’t fair to assume a quality of engineering or product based on the location of where product is assembled or where the headquarters of the business is operating.

It’s deceptive and misleading to suggest the quality of a product can be determined solely from its country of origin, especially if the suggestion is that a product made in Asia is created to a lesser standard, when compared with other non-Asian markets. In 2013, it was reported that over 90% of solar panels imported to Australia were made in China, despite the popular non-Chinese brands being prevalent in the offers from retailers.

With such high level of market penetration from solar PV brands from China, the quality gap is broad, making the importance of differentiating quality is why some manufacturers stay in business and others don’t.

5. Doesn’t all solar PV manufacturers provide the same warranty protection?

Australia is one of the world’s most dynamic retail residential markets, and with a flood of messages in the industry, it has been easy to think that if a solar panel offers a 25 years (performance) warranty, then you will be protected?

This is true, but only to an extent.

The 25 years warranty is a performance warranty pertaining to minimum expected performance or output year on year. This is separate to the performance of the system as a whole, which is subject to the system design and performance of other components.

Although many customers are sold on the belief that there would never be a fault, this is largely misleading and for the following reasons:

- The technologies are well proven, so are installation done by people, and human error is always an unquantifiable risk.

- Transportation risk can affect a product, it’s unlikely that defects from transportation show.

- The technology is exposed to the outdoor environment, which is subject to wind, rain, dust, dirt and bird droppings, trees, twigs, possums – just to name a few.

So, do buyers ask – what is the process in the unlikely event of fault or failure?

- How do I know?

- Is the system being monitored? Is the monitoring only for the homeowners viewing, or is there a back to base system which communicates to you, the owner and also the installer?

- What happens if you don’t know or can’t find the installer?

- Who supports the installer?

- What are your consumer rights?

- Do the major component suppliers have a local representative? If so, who are they and what is their phone number?

Performance warranties are valid if there is adequate evidence to suggest your performance is less than designed. Regardless, an assessment will need to be done, preferably by the company or installer who sold you the system. If they cannot be found, then buy from a reputable and industry-qualified professional.

6. It’s all about price!

It’s a common reality in buying anything, when in doubt, select the best value for money. This suggests that value has been presented, on the contrary, the lowest cost solar is no exception. In many instances, the lowest cost components generally require a higher level of repair and replacement – the consumer may not be aware of this, and it will cost them more in the long run.

With any capital investment, you want certainty in the unlikely event of any fault or failure, above and beyond long-term guarantees.

It is strongly encouraged that you conduct research about some technical differences, and have a list of questions about how you will receive after-sales support and service. The reality is if you don’t understand the differences, the only value you can see is one based only on the price.

7. Capabilities of product and installer

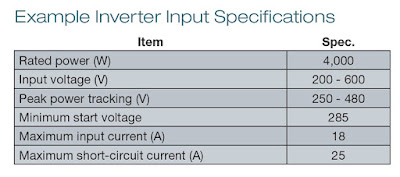

With such an expansive list of products and installers – it can be difficult to know the good from the not so good. The buying market has no point of reference to determine if a solar panel or inverter is good versus average – as it is based on Clean Energy Council’s approval.

Aside from generic references, which are meant to instill confidence, like “we have installed over 3,000 systems”, there is no means for buyers to understand the experience or quality of services they are paying for.

One of the biggest concerns is whether the installer is based locally, and we suggest you to ask these questions:

- If the installer does not have a local office, have you enquired their service standards and response times in the unlikely event of a fault?

- What is the policy and commitment of the after-sales service?

- What is their responses time frame?

- Is there a difference in receiving service within 48 hours or over 4 – 8 months?

There are many fantastic and integrated installers in the market but unless a series of questions are being asked, how will a solar buyer know? The age-old method of testing this is to ask for references, preferably from people in similar situations as you, and a customer who had bought from them previously.

We encourage those interested in solar to do their research, the team at Yingli Solar are available to help answer any products, services or technical questions you may have!

We in the Philippines can help you to install Yingli Solar for your energy needs. Please send your email to inquiry@eastgreenfields.com or call/text 0917-8232530.